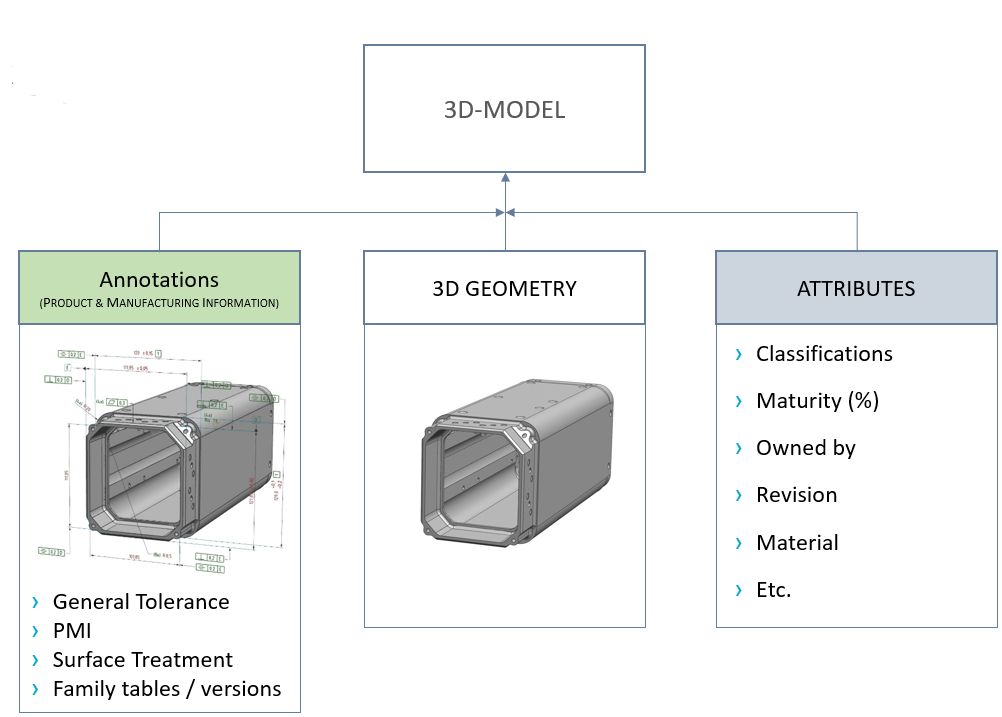

Model Based Definition: To use an annotated 3D-model with attributes as governing document. To handle the data in the way it becomes system readable and what rules to follow to get there. Benefints of using one fileformat containing both geometry as well as all other requirements such as metadata and attributes.

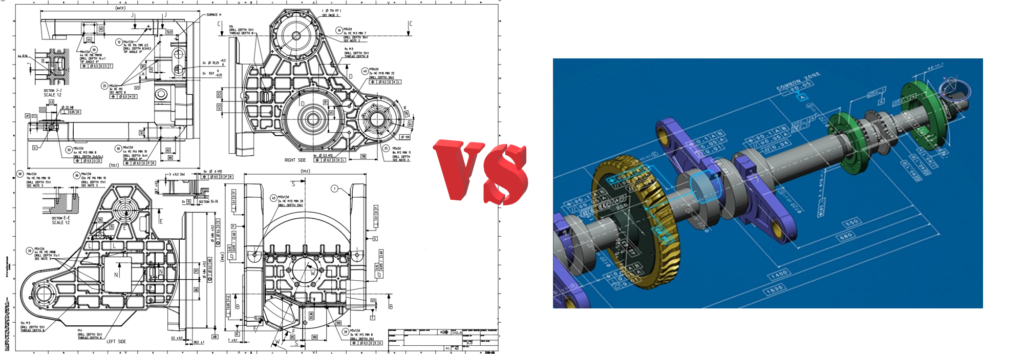

This webpage will discuss going from using 2D-drawings as governing document to MBD, and how it is used on part and assembly level.

Picture showing a MBD 3D-model, that not only contain the geometry, it should also include annotations as well as attributes.

Share knowlege are success for mid and small size companies.

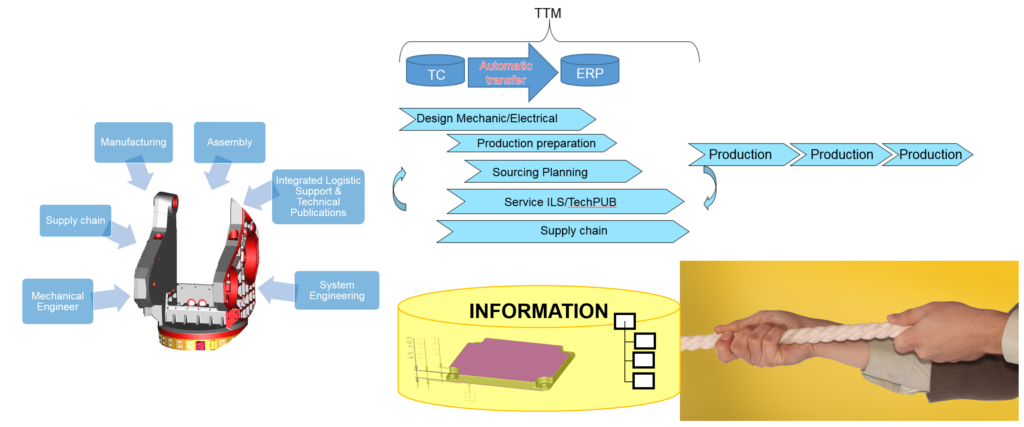

In a world where every company focus on there core business, fewer and fewer got capability to both be great at product development as well as production. We must realize that use of information must be as seam less as possible not only within a company’s different groups, it must also have the same properties when used by other in the loop for example suppliers.

My opinion are: Best way of sharing data, are to look at the same database and give different users different access depending on what role they got. What I try to say is, do not send files back and forward, especially not via email, it is not safe and to keep track of revisions are hopeless… I guarantee that you will receive wrong produced parts because of human errors. With good system support could even suppliers comments be included in correct revision inside your PLM system.

It has historically been a fight between giants to create own software and tune the systems with help of IT personal to support companies’ methodology. Car industry been leading. To have the most streamlined PLM solution to reduce TTM (Time To Market), it has created a 5th wheel of own written software. Today are the software so mature that best way of using it are to configurate to obtain wished way of working, not create own adoptions and software. This also result in easier upgrades of software.

An annotated 3D-model carry both geometry as well as all metadata. This gives ONE governing document to get all information from. This leads to reduced amount of conflicts and errors. The picture are actually wrong… the 2D-drawing should ofcourse got an 3D-model like STEP, since very few use only 2D-drawing. (But in some products is it enought, like some sheet metal parts, or gaskets…)

Standard

“Best knowned way of working, right now”. To understand that a company always must be in constant development of both products as well as processes to meet demand should be every companies core business. How much has your processes been developed past 30 years?

Use tools “Out-Of-The-Box”

Software has become so mature that you prefferable use them out-of-the-box and simply configure them to your processes, old school of uniquly developed functions are not needed.

Type data once

Use system support so you only have to write data once, and re-use it downstream are vital to reduce human errors. To fill in data can also be checked by system to be verified that all data are correct.

Telefon

+46 (0)72 449 88 22

Email

Per.Gabrielsson@MBDSweden.se

Adress

Snårvindevägen 271

165 74 HÄSSELBY

Behöver du hjälp?